shafting

SHAFT FAILURE

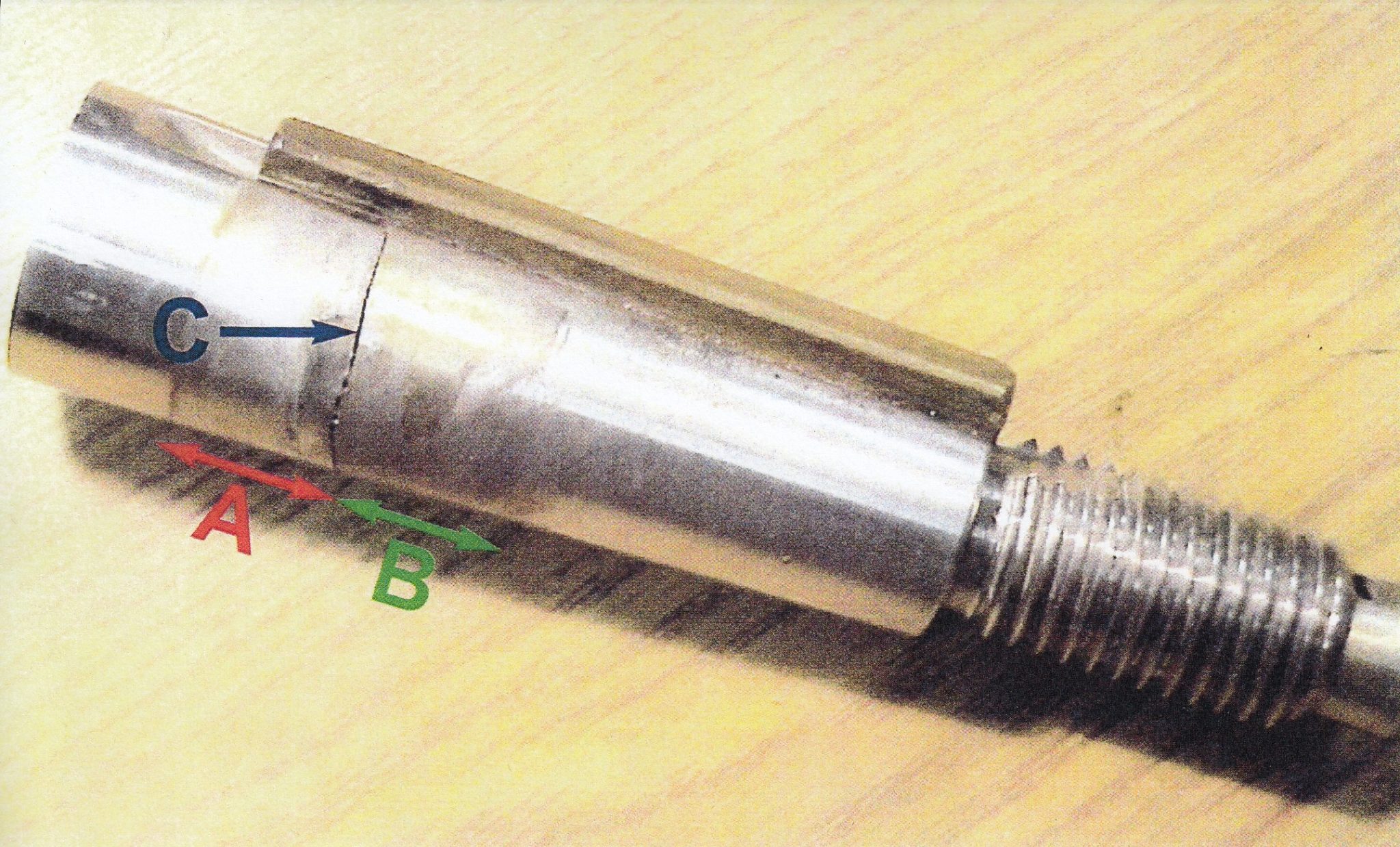

As shown in the example below, the contact area (A) between the propeller hub and the shaft was only about 25% of taper. The area of discoloration (B) was caused by rubbing. A fatigue crack (C) has propagated through part of the shaft cross section.

The vast majority of failures are related to improper fit between the shaft taper and the propeller hub taper, either due to imperfectly mating surfaces or high keys. The contact area should be a minimum of 70%. Over the years, we have seen contact areas as low as 20%. When the contact area is too small, the forces created by the blades can set up a slight wobble in the propeller, which may or may not be felt by the boat user. If the frequency does not hit a harmonic wavelength in the boat’s propulsion system, it is not amplified, and you may never perceive that your hub is wobbling. However, this wobble sets up conditions which will ultimately result in a fatigue failure.

The term “fatigue” describes a metallurgical fracture mechanism due to cyclic stress, i.e. a continual cycle of loading and unloading. Over time, a small transverse (circumferential) surface crack or cracks will appear and gradually propagate through the cross section until final overload fracture occurs.

An extreme but well-known example of fatigue is bending a paper clip back and forth, gradually fatiguing the meal until it breaks. Compared to bending paper clips, most field fatigue failures experience only slight “bending” and may take very long times from crack initiation to ultimate fracture.

10 Brammer Drive

Orillia Ontario

L3V 7T4

OFFICE HOURS

Mon - Thurs 8:00am - 4:30pm

Friday 8:00am - 12:00 noon

Weekends closed