PROPELLER / SKEG REPAIR

We are the largest propeller repair facility in Ontario. We repair all propellers from a size range of 5” to 5 feet! We repair aluminum, stainless steel, bronze and nibral propellers. We have a state of the art facility and are the only Prop Scan facility in Canada.

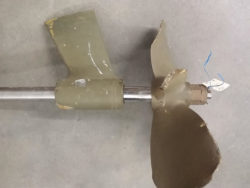

Many people often wonder what happens to their propellers during repair.

When an aluminum/stainless steel propeller arrives here at our facility, it is inspected and given a reference number – which is stamped onto your propeller to ensure that you get your own propeller back.

The propeller is then sandblasted. We then straighten the blades on the correct pitch block for the pitch of the propeller. Next the propeller moves on to the welding area where the propeller is welded to add material for any missing “chunks or nicks”. Then the welded areas are ground so that the propeller blade is smooth. Pitch is checked again to ensure that the pitch was not compromised during the welding stage. The blades are then matched and balance is checked. Aluminum propellers are then readied for paint and stainless steel propellers are brought to a “satin finish” and the cup is checked to ensure that the cup that the propeller arrived with is the same as when the propeller leaves. Stainless steel propellers are then checked one last time for balance. The next stage for both types of propellers is Quality Inspection. We check each and every propeller/skeg for quality. If a propeller does not pass, it goes back into the system again as we are proud of our work and want to ensure that it is a quality repair. We stand behind each and every repair that we do.

For inboard propellers (bronze and nibral) that arrive here at our facility, the process is similar to the aluminum and stainless steel propellers. Inboard propeller repairs are usually quoted. Once approval has been received, the propeller repair will begin. All propellers are scanned using Prop Scan. Prop Scan is a “tool” that we use to ensure the accuracy of each and every repair. Inboard propellers are sandblasted, straightened, welded and ground in a similar manner to the aluminum and stainless steel propellers with the exception that the Certified Propeller Technician will work in tandem with Prop Scan, ensuring they correct any accuracy problems, apply the correct section form and also tune the pitch of your propellers. Once the technicians are pleased with the repair, the propeller is sent to the “finishing” department. The cup and balance will be checked. A report will be generated and will be analyzed by our Quality Control Department. You will be supplied with a Quality Certificate that guarantees the quality of our work.

We repair skegs to all makes of lower units. To have a skeg repaired, we only require the lower half of your unit (it needs to be split from the upper) and the unit needs all oil drained.

During a skeg repair, we remove the damaged skeg and weld on a replacement aluminum casting. All other repairs are done, such as repairs to the bullet, cavitation plate etc. and then the unit is prepared for the paint process. The unit is checked for quality and then returned to the customer.

We are often asked our thoughts on skeg protectors. We do not advise the use of such products. The skeg is designed to break in case of impact. When skeg protectors are used, the skeg is strengthened and when/if an impact occurs, the skeg usually breaks at the bullet area or above, causing a hole or crack in the lower unit or worse. The repair would then be more costly than if a protector was not used.

- If you haven’t hit a rock, you haven’t left the dock!

- Josh K.: Propeller Repair Aluminum/Stainless Steel

- Inboard Propeller Repair

- Reuben: Propeller Repair/ Skeg

- Propeller Repair – Stainless Steel

- Skeg Repair

- Inboard Propeller Repair

- Propeller Repair – Aluminum and Stainless Steel

- Josh F. – Propeller Repair – Aluminum and Stainless Steel

- Carlene – Propeller Repair – Aluminum and Stainless Steel

- Carlene – Propeller Repair – Aluminum and Stainless Steel

- Josh K. – Propeller Repair – Aluminum and Stainless Steel

- Propeller Repair – Aluminum

- Reuben – Aluminum Propeller Repair

- Skeg Repair

- Josh K. – Propeller Repair – Aluminum and Stainless Steel

- Carlene – Aluminum Propeller Repair

- Propeller Repair – Aluminum

- Inboard Propeller Repair

- Stuart – Propeller Repair – Aluminum

- Reuben – Propeller Repair – Aluminum and Stainless Steel

- Propeller Repair – Stainless Steel

- Propeller Repair – Aluminum and Stainless Steel

- Propeller Repair – Aluminum and Stainless Steel

- Propeller Repair – Inboard

- Propeller Repair – Inboard

- Propeller Repair – Inboard

10 Brammer Drive

Orillia Ontario

L3V 7T4

OFFICE HOURS

Mon - Thurs 8:00am - 4:30pm

Friday 8:00am - 12:00 noon

Weekends closed